We have been helping electronic brand-owners and manufacturers worldwide to bring high quality products to customers. Leveraging our core competences in electronics manufacturing services (EMS) and profound production base in China and Vietnam, SUGA has strategically expanded and diversified its businesses to offer Product Solutions and Services for electronic market primarily and Sales and Distribution Services in pet market.

SUGA High-tech

Industrial Park

SUGA High-tech Industrial Park in

Dongguan City, Guangdong Province

of China, has started operation in 2014. The new factory combines production facilities that were previously located in Shenzhen and Huizhou. Production capacity are boosted with the installation of automated equipment, and production efficiency and procedures are further enhanced.

Location: Qingxi Town, Dongguan

Total Factory Area: 1,000,000 sq. ft.

Total Employees: 2,000

SUGA's Vietnam Plant

SUGA’s Vietnam Plant involves more automated production processes, mainly non-labor intensive parts. The Group will flexibly allocate resources and adjust its production scale according to its customers’ needs.

Location: Bac Ninh Province, Vietnam

Total Factory Area: 30,000 sq. m.

Total Employees: 1,000

Offering Services: SMT lines, PCBA lines, Final Assembly lines

Services:

Electronic manufacturing, hardware design, industrial design, mobile apps, plastic injection molding, mold making.

Products:

Professional audio, smartcards, near field communication (NFC), consumer electronics, IoT & connectivity, smart personal care products.

Quality Assurance

- ISO 9001:2015 (Quality Management) certified since 2015, certificate No. 00118Q31113R1M/4403

- ISO 14001:2015 (Environment Management System) certified since 2015, certificate No. 00118E30439R1M/4403

- ISO 13485:2016 (Quality Management, Medical) certified since 2016, certificate No. MD 646563

- QC 080000:2017 IECQ HSPM Certification (Hazardous Substance Management) certified since 2018, certificate No. IECQ-H SGSCN 09.0064

- HONG KONG GREEN Mark Certification SCHEME (Environment Management) certified since 2007, certificate No. G1006-CN1

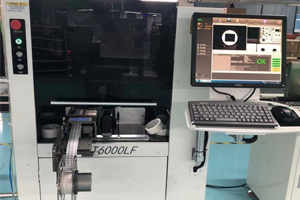

Production Equipment

-

Surface mount technology

- 11 SMT FUJI / YAMAHA high speed production lines

- CPH: 15210800

- Max / Min component size: 1005~45×150(68×68)mm; 45mm SOP, SOJ, QFP, PLCC; 0.4Picth QFP, QFN, BGA; W45×L100mm Connector IC Socket; H(MAX): 25.4mm

- Automatic Optical Inspection

- Solder Paste Inspection

- X-RAY Checks Equipment

- DIP / AI Plug-in

- COB Bonding

- Automatic Offline Burning

-

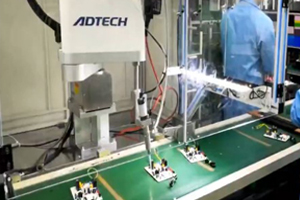

Production lines

- Wave soldering lines

- Hand soldering lines

- Casing assembly lines

- Ultrasonic welding lines

- Automatic testing lines

- Packaging lines

-

Production lines equipment

- Auto Soldering machine

- Barcode labeling machine

- Auto programming machine

- Solder paste unfreeze machine

- Automatic visual gluing machine

- Smart shelf

- Semi-Auto Casing assembly line

- Battery Packing line

- Conformal Coating machine

-

Touch panel/LCD module assembly

- Class 100~1000 (ISO14644-1)

- Air velocity: 0.45m/s

- Air flow:900~1800m3/h

- HEPA: 99.99%@0.3um

- Noise level: <60dBA

-

RF parameters

- Attenuation 70~75dB

- Frequency 100MHz~2.4GHz

Research & Development Facilities

-

- IQxel80/IQView

- Oscilloscope

- Spectrum analyzer

- Power meter

- Logic analyzer

- Electronic load

Test Equipment

-

General testing equipment

- RoHS tester

- Reliability/Environment tester (ASLI/ESPEC TH-1650DH-5.0/SETH-Z-102R)

- ICT tester (TR518)

- Telephone ATE test equipment

- AP tester

-

Special testing equipment

- Wi-Fi tester (802.11b/g/n):LitePoint IQ series

- Microphone Acoustic Test System (Type-2718)

- 4G Communication Tester (CMW500)

- Wireless Network Tester (IQ Flex IQF02761 / IQv03220)

Mold Making Facilities

-

Mold making equipment

- CNC machines

- EDM machines

- Wire-cutting machines

-

Plastic injection molding equipment

- Plastic injection machines

- Clamping force: 50 – 1300 tons

- Double injection

- Vertical Injection

- Insert molding

- PMMA / Lens

- Max. product size:

Weight: 3,300g

Size: 135cm x 80cm x 10cm (LWH)