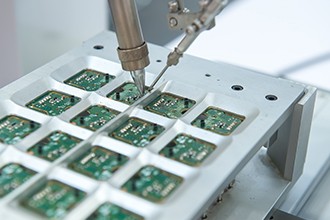

We have extensive experience in the injection molding of engineering-grade materials for automotive parts, telecommunication products, consumer electronics products, home appliances, industrial components, and double injection and insert molding products. We can produce plastic parts by using Polycarbonate (PC), Acrylonitnile Butadiene Sytrene (ABS), PC and ABS Blends, Ployacetal (POM), Polymethly Methacrylate (PMMA), Polyamide (PA), Polybutylene Terephthalate (PBT), Polyethylene (PE), etc.

With regards to our plastic injection capability, our plastic injection machines are able to satisfy a wide range of demands, i.e. double injection, vertical injection and insert molding as well as the production of PMMA lenses. Our plastic injection machines' clamping force between 50 tons and 1,300 tons can meet product weight up to 4,500g and LWH.

To facilitate the application of various surface finishes, we also have secondary operation such as spray painting, PU and UV painting, silk screen printing and pad printing, ultrasonic welding, laser engraving and hot stamping.

We provide accurate critical dimension inspection and full dimensional inspection by employing a variety of precision inspection equipment, such as CMM, projector, microscope, electronic height gauge, digital caliper, etc.

Our experienced team of professionals can answer your inquiries at any time. If you need further information about our solutions, please send an email to sales@suga.com.cn.